What Is A 3D Printer?

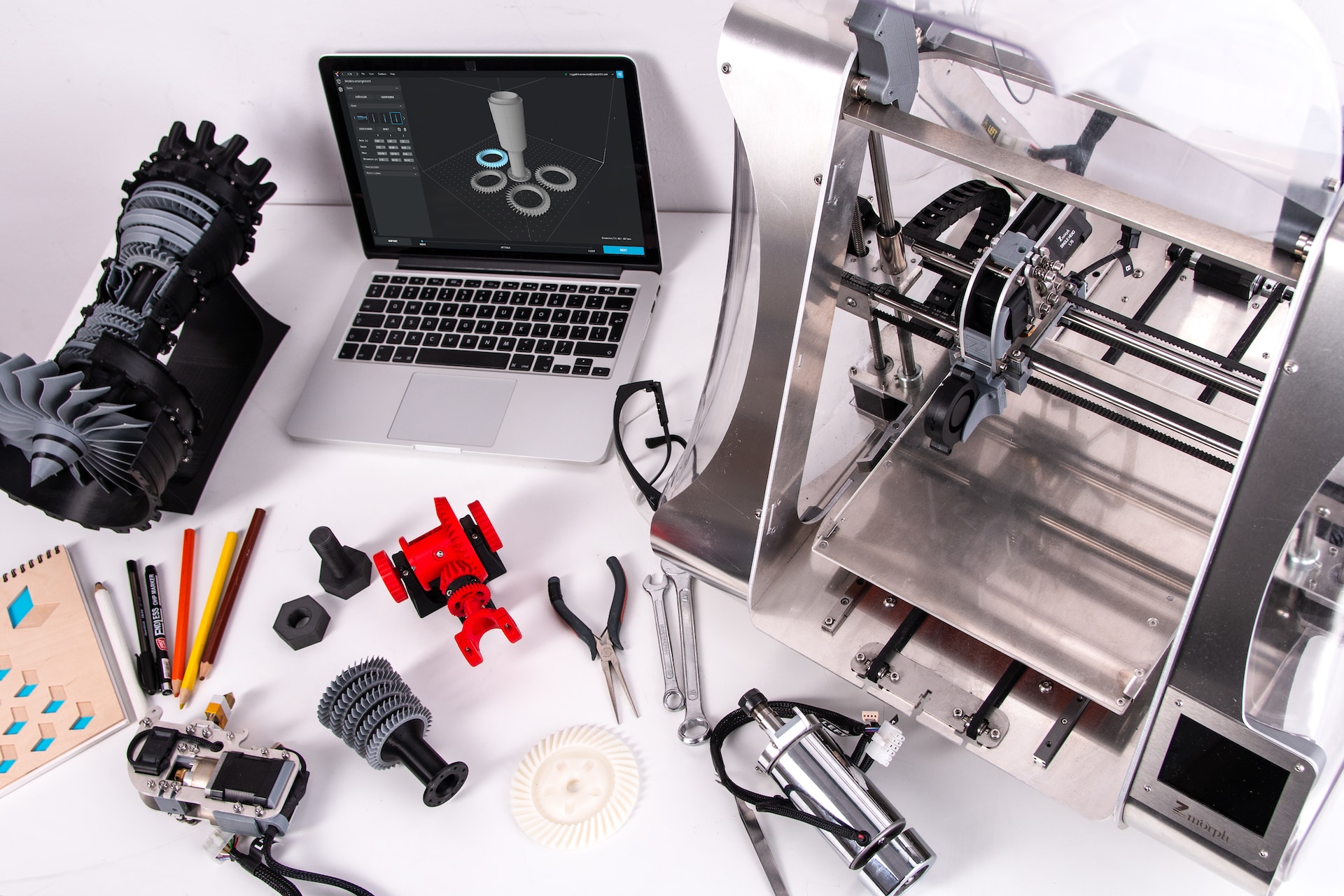

The process of 3D printing begins with the creation of a digital model or design. This can be done using a variety of software programs, including CAD software, 3D scanning software, and even video game engines. Once the digital model is created, it is saved as a standard file format, such as STL or OBJ.

The 3D printer then takes this digital file and translates it into a physical object by printing it layer by layer. The printer lays down a layer of material, such as plastic or metal, and then moves up to print the next layer. This process is repeated until the entire object is complete.

There are several types of 3D printing technologies, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). FDM is the most common and uses melted plastic that is extruded through a nozzle to create the object. SLA uses a laser to cure a liquid resin into a solid object, while SLS uses a laser to fuse powdered materials together to create the object.

How Does It Work?

One of the benefits of 3D printing is the ability to create complex geometries and shapes that would be difficult or impossible to create with traditional manufacturing methods. Additionally, 3D printing allows for customization and personalization of objects, making it a popular tool in the medical, dental, and jewelry industries.

3D printing also has potential for reducing waste in manufacturing, as it allows for precise production of parts and objects. It can also be used to create prototypes and test models, allowing for faster and more cost-effective product development.

In conclusion, 3D printing is a type of manufacturing technology that creates three-dimensional objects by layering materials in a specific pattern or design. It works by reading digital blueprints created with computer-aided design software and translating them into a physical object. There are several types of 3D printing technologies, each with their own benefits and drawbacks. 3D printing has potential for reducing waste, customization and personalization of objects, and faster and more cost-effective product development.

What Is It Used For?